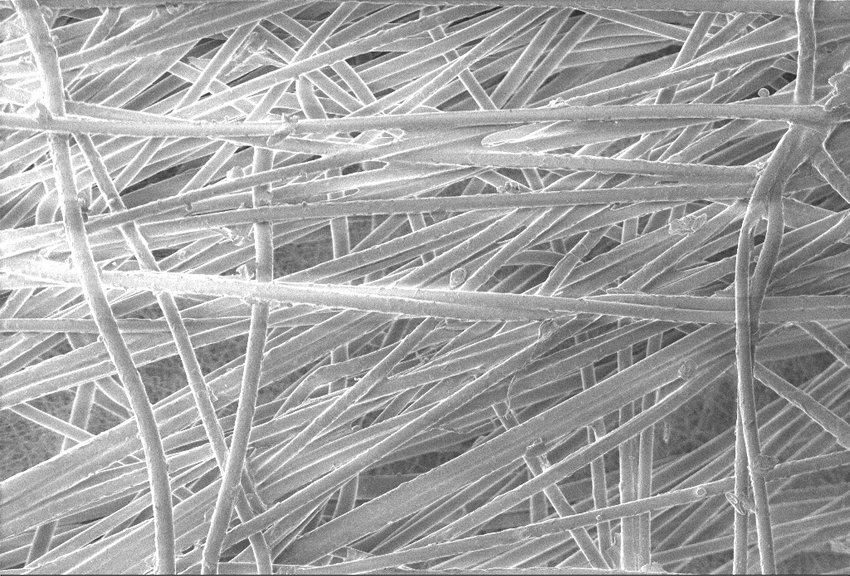

Electrospinning is a rapidly developing technique for producing micro or polymer-based nanofiber with high-quality characteristics in the textile industry, especially wound dressing, tissue engineering materials, drug delivery systems or coating techniques in the medical world. This technique uses electrostatic forces to form fibers at nano or micro scale. This technique could obtain a 10 nm diameter. One of the most influential parameters is the viscosity of the solution. The viscosity of the solution will determine the morphology of the nanofiber membrane. Research from Sukigara et al. (2003) stated that long and fine fibers could not be obtained with solutions that have low viscosity. On the other hand, high viscosity will bring irregularities in the fibers produced by this process. So, the determination of solution viscosity has an important role in producing high-quality nanofiber.

Several studies have been conducted to produce nanofibers with the best quality using polymers such as Polyvinyl Alcohol (PVA), Polycaprolactone (PCL), Polyethylene Oxide (PEO) and other polymers. PVA is a polymer that is famous for its hydrophilic properties which easily form hydrogen bonds from its chains. PVA with a concentration of 10 wt% in water can be used as electrospinning material with a high voltage of 5-20 kV with the results of nano-sized fibers. The weakness of this result is the appearance of clots or beads along the fiber, and it is not expected because it will affect the mechanical properties of the fiber because PVA molecules tend to that have strong bonds and are difficult to pull in by voltage differences and eventually form clots. For this reason, additional material is needed to reduce the appearance of these clots. These additives can be active components, such as Aloe vera extract which also has other effects on the fibers.

The study conducted by Abdullah (2014) showed that Aloe vera could attach to the PVA chain and possess a suitable structure to be applied as a biomaterial because of its biodegradability, biocompatibility, and non-toxic properties. Aloe vera has already used in biomaterials as an additive that can support the healing process of wounds in wound dressing. Aloe vera has also been widely used to treat burns over the years. Furthermore, a study from Isfandiary et al. (2017) on the use of Aloe vera in chitosan and collagen-based wound pads showed that the presence of Aloe vera in these biomaterials gives benefits to be applied as a wound dressing. The results of a review article from Venugopal et al. (2014) and Khan et al. (2018) reported that the presence of Aloe vera in a mixture of nanoparticles had been proven to accelerate wound healing and provide better treatment for wounds. Aloe vera also has good antibacterial properties.

The conducted research aims to see the effect of viscosity of PVA and Aloe vera mixture resulted from differences in the used concentration for the characteristics of produced nanofibers. The concentration of Aloe vera were 0, 2.5, 5, 7.5, and ten wt% with PVA concentrations of 10 wt%. Both are then mixed with a ratio of PVA and Aloe vera of 70:30. The solution produced from this mixing process is then processed through electrospinning with a high voltage of 19 kV and the distance between the needle and collector is 20 cm. The produced nanofiber sheets were then characterized using Fourier Transform Infrared (FTIR), Scanning Electron Microscope (SEM), Differential Scanning Calorimetry (DSC), and degradation test using Phosphate Buffer Saline (SBF).

The result of functional group characterization using FTIR showed that there was an absorption shift in the sample due to the hydrogen bond between PVA and Aloe vera. The use of Aloe vera in this mixture also increases the size of the fiber as the concentration of Aloe vera is increased. The results of the thermal analysis using DSC showed that there was a shift in glass transition temperature and melting point temperature. It provides information about the durability of the sample. However, the shift is not too drastic. The results of the degradation test imply that the PVA chain is complicated and the existence of Aloe vera in the mixture can extend the time required by the sample to be degraded so that it shortens the rate of degradation of the membrane.

From the results of this research, it can be concluded that the addition of Aloe vera to the PVA solution to make nanofiber membranes through electrospinning can improve the characteristics, in terms of morphology, thermal analysis and degradation. For future research, it is necessary to study the effects of various parameters that affect the electrospinning process and optimize the results of the obtained nanofiber membrane.

Author: Alfian Pramudita Putra, S.T., M.Sc.

Our research has been presented at the 8 th International Conference on Theoretical, and Applied Physics (ICTAP) in 2018 and the results were published on the following link:

https://iopscience.iop.org/article/10.1088/1742-6596/1120/1/012096

D. Hikmawati, A. R., Rohmadanik, A. P. Putra, Siswanto, and Aminatun, “The Effect of Aloe vera Extract Variation in Electrospun Polyvinyl Alcohol (PVA)-Aloe vera-based Nanofiber Membrane”, J. Physics: Conf. Series 1120 (2018) 012096.